EM-KLEEN in-situ remote plasma cleaner

PIEM100

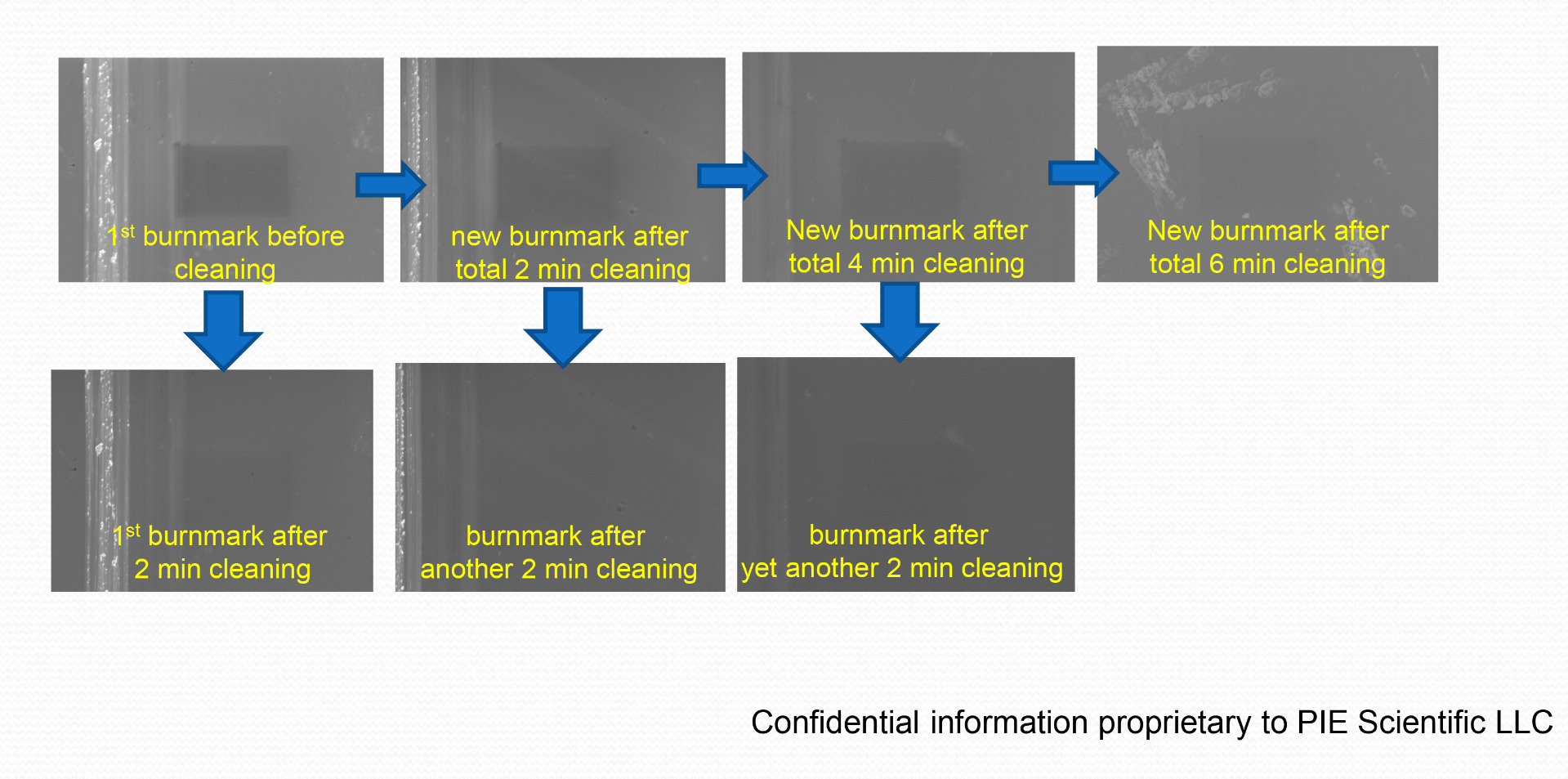

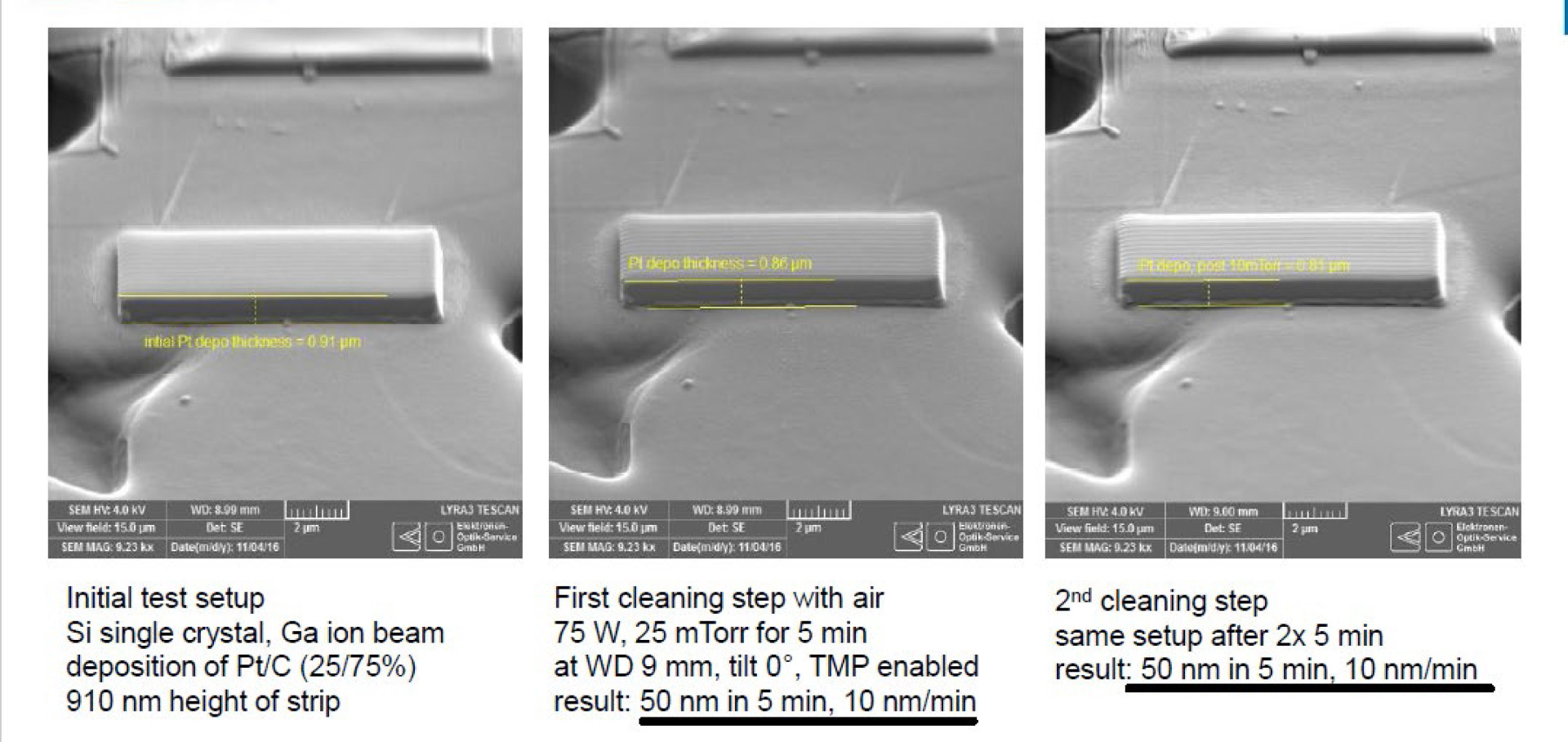

The EM-KLEEN in-situ remote plasma cleaner can be used for in-situ cleaning of samples and vacuum chambers for electron microscopes and other types of analytical instruments, such as SEM, FIB, TEM, XPS and SIMS. It can effectively remove hydrocarbon and fluorocarbon contaminations inside the vacuum chamber as well as organic contaminations on the surface of the sample before imaging and analysis.

Product Details

Description

Specifications

- Tabletop controller with embedded microcomputer and LCD touchscreen user interface

- Remote plasma source (high quality quartz tube) with KF/NW40 vacuum interface

- PC remote control software with intuitive user interface

- 60-recipe support in microcontroller

- 75 Watt RF power supply, no need to adjust impedance matching

- Plasma sensor for plasma strength monitor

- Electronic gas flow control with pressure sensor feedback control

- Smart-Schedule feature for automatic cleaning

- Intelligent safe and expert operation mode

- 15 feet high quality high power RF cable; D-Sub 9 PC control cable; D-Sub 15 source control cable.

Application Examples

The EM-KLEEN is a fully automatic plasma source. The system consists of a resistive LCD touchscreen controller with an embedded microcomputer and a remote plasma source. The design is intuitive and versatile.

Despite its small size, the EM-KLEEN remote plasma source has an integrated Pirani pressure sensor, an electronic gas flow controller, a plasma intensity sensor, a temperature sensor and a cooling fan. The flow controller automatically adjusts the gas flow rate to maintain recipe-specified pressure inside the plasma cleaner chamber. The controller can store up to 60 recipes with different RF power, plasma tube pressure, gas flow rate and cleaning duration. No manual adjustment is required for different recipes. The miniature pressure sensor constantly monitors the sample chamber pressure.

It can be used as a safety interlock trigger in the safe operation mode or to count sample loading events for the SmartSchedule™ feature. A cooling fan enables high-power high-speed cleaning without causing the source to overheat. The temperature sensor provides another interlock protection against source overheating during prolonged cleaning processes at high power. The plasma strength sensor measures the plasma strength in real-time, users can monitor the plasma status.

With pressure sensor, automatic gas flow controller, plasma sensor, temperature sensor, and LCD touchscreen controller with embedded microprocessor working in tandem, EM-KLEEN in-situ plasma cleaner can take care of your system automatically and provide protection against potential user mistakes. SmartClean™ technology developed by PIE Scientific combines the state-of-the-art plasma source design technology developed in nuclear research and in the semiconductor industry. EM-KLEEN plasma cleaners are far more advanced than previous generations of remote plasma cleaners and bring many unique features.

The standard vacuum interface port is a NW/KF40 flange. Adapters for different SEM ports are available. CF2.75″ flange option is also available.

More Information

| Manufacturer |

PIE Scientific

|

|---|---|

| Packing Unit | each |

| Weight | 0.000000 |