All you need to know about anti-vibration platforms

Vibration isolation platforms support your application to dampen external vibrations and acoustic noise that could adversely affect your application. To control environmental conditions active and passive systems can be chosen for specific requirements . This is particularly important for experiments or processes in which typical amplitudes of the ambient vibrations are of similar dimension compared to the structures that are being studied or fabricated.

In microscopy for example, anti-vibration platforms are used to stabilize the image, especially during high-resolution long-term exposures and using laser scanners. In ultramicrotomy, vibrations can lead to falsification of the section thickness and flatness. Vibration isolation platforms decouple systems from vibrations in order to achieve an optimal result.

Depending on local conditions, requirements and applications, platforms are available in various sizes and configurations and can be combined with acoustic, electric and/or magnetic field insulation. We offer active and passive platforms that can be placed on laboratory benches and workbenches, as well as complete anti-vibration tables.

We support you in selecting the right platform for various systems such as microscopes, (ultra)microtomes and other measuring and process devices.

Without anti-vibration platforms support / With anti-vibration platforms support

A basic distinction is made between passive and active anti-vibration platforms and tables:

Passive anti-vibration platforms:

Passive anti-vibration platforms:

In principle, passive anti-vibration platforms work as a system of spring and damping elements. The disadvantage of this system is that it has a natural/resonant frequency at which vibrations are amplified. However, technical solutions exist that significantly reduce these resonances and bring them down to a low-frequency range (1-8Hz). The transmission of vibrations decreases sharply at frequencies above the resonant frequency.The platform and the device to be dampened are isolated from these external vibrations.

Such passive spring-mass systems are built into the feet of platforms, while vibration-damping tables have a heavy tabletop mounted on compressed air dampers that perform the same function.

The weight and the weight distribution of the device to be isolated are crucial for passive vibration isolation systems. Passive platforms therefore have a defined functional area that must be coordinated with the respective device. Advantages are the lower purchase price (compared to active anti-vibration platforms) as well as their flexibility and mobility.

>> Klughammer Anti-Vibrations Plattforms

Active anti-vibration platforms

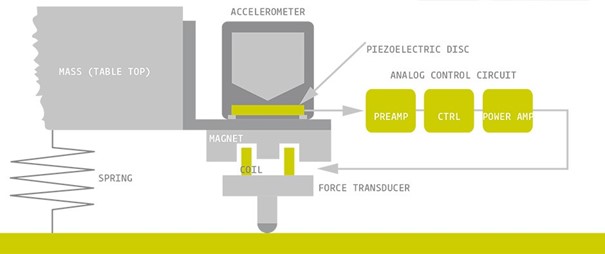

In active anti-vibration platforms, the signals detected by extremely sensitive accelerometers are analyzed by electronic circuits which in turn drive electrodynamic actuators that immediately generate a counter-force to compensate for the vibration. This is also referred to as active vibration control (AVC).

Active vibration isolation systems exhibit no inherent resonance or amplification of vibrations which is a significant advantage over passive isolation systems. Likewise, moderate weight changes or movements on the platform are possible without restricting functionality.

Principles of Active Vibration Isolation Technology by Accurion

Principles of Active Vibration Isolation Technology by Accurion

Vibration-isolated tables

Vibration-isolated tables

Vibration-isolated tables decouple devices from vibrations that originate in the room, the building and/or in its surroundings. They are mostly passive systems atopwhich e.g. complete laser scanning microscopes or ultramicrotomes can be placed. Actively isolated tables with integrated active vibration control (AVC) are also available for ultra-sensitive applications on a larger scale.

In passive anti-vibration tables, uneven weight distribution can be compensated for by adjusting the shock absorbers, meaning that complete systems including their control units can be accommodated on the tabletop. To operate passive anti-vibration tables a compressed air connection regulable to 5 - 6 bar is required, provided for example by a house line, a quiet compressor or a compressed air bottle.

Active tables only need a flat and stable base as well as a standard power connection.