Tergeo EM Tabletop Plasma Cleaner for Electron Microscopy

PIETE100

The Tergeo EM plasma cleaner is a laboratory tabletop plasma system designed for TEM and SEM samples, grids and holders. It can accomodate up to two TEM holders or two 4″ wafers.

The Tergeo plasma system can operate in two cleaning modes: Immersion plasma cleaning for high speed etching and surface modification and remote plasma cleaning for gentle surface contamination removal, such as SEM/TEM sample cleaning. With pulsed operation for extremely delicate samples, plasma with an average RF power of less than 0,5W can be generated.

Product Details

Description

- Integrated direct immersion and remote downstream cleaning modes

- Plasma sensor for real time plasma intensity measurement

- Pulsed operation down to millisecond pulses

- All-in-one laboratory plasma etching, treatment and cleaning system

- Large sample chamber for batch processing. Quartz tube inner diameter: 110mm, depth 280mm. Quarz sample tray: 100mm x 250mm

- Dual TEM holder adapter can be configured to support TEM rods from two different vendors

Direct and downstream plasma cleaning modes

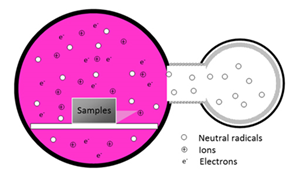

Immersion mode plasma cleaning

Immersion mode plasma cleaning

Plasma is generated inside the sample chamber. Samples are immersed in plasma for efficient removal of organic contaminations, depositions, surface treatment or photoresist ashing.

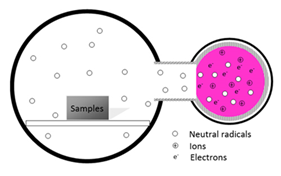

Downstream mode plasma cleaning

Downstream mode plasma cleaning

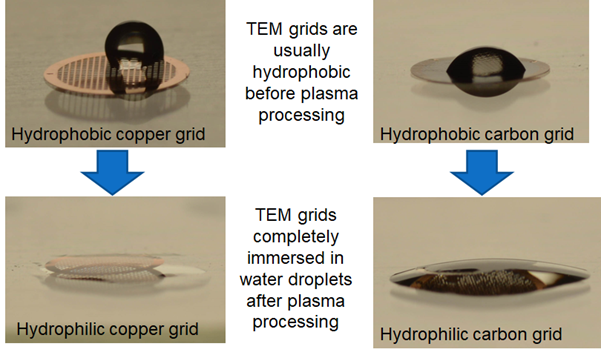

Plasma is generated outside sample chamber, samples are not immersed in plasma. Only gentle chemical reaction takes place on the sample surface. No energetic ion sputtering!

Used for fragile thin film such as carbon coated TEM grids and heat sensitive composites, polymers, biological samples, etc.

Sample loading methods

20x TEM sample holder (green) can be placed directly on the quartz shelf. The chamber can hold up to 6 of these holders (120 grids).

Quartz sample shelf, with holes for the standard SEM stubs.

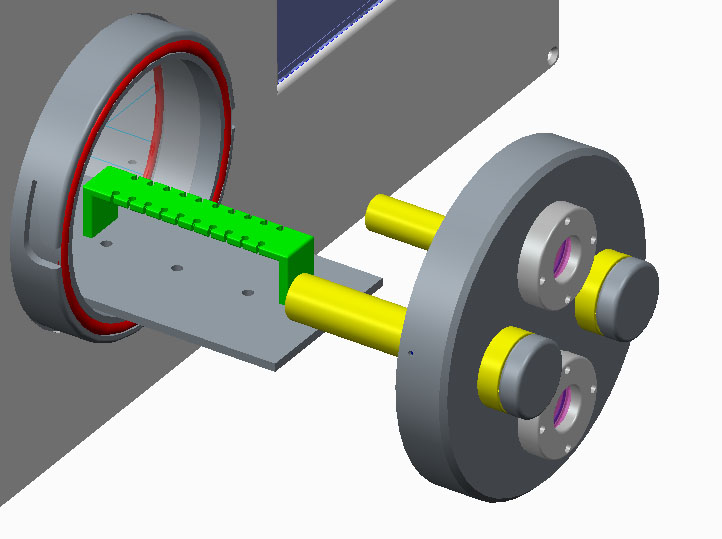

Clean two TEM sample rods (yellow) at a time. Simply take the cap out and insert the TEM rods.

The front door can be taken out to access the sample chamber. The door is firmly locked on the chamber during normal operation.

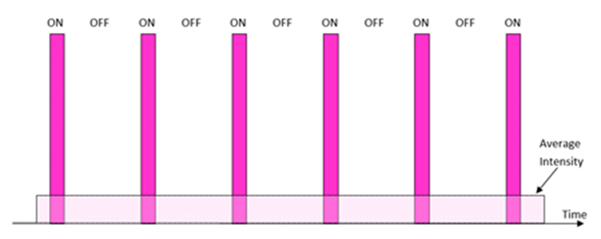

Pulsed operation

The Tergeo-EM plasma system can generate continuous or pulsed plasma.

The Tergeo-EM plasma system not only adjusts RF power, but can also adjust the pulse duty ratio. Pulsed mode further extends the dynamic range of the plasma intensity. The pulse duty ratio can be adjusted from 100% (continuous) to less than 1%. The plasma intensity varies more linearly with the pulse duty ratio compared with adjusting the RF power wattage. Pulsed mode can create an extremely weak plasma that is almost invisible to human eyes, but the proprietary plasma sensor can still measure the plasma intensity quantitatively.

Pulsed mode can generate weak yet repeatable plasma for fragile samples like 2D materials, TEM holey carbon grids and other samples that can be easily damaged by strong plasma.

Quantitative plasma intensity measurement

Take the guesswork out of plasma cleaning. The plasma sensor tells the user exactly how strong the plasma is. Use the quantitative plasma intensity measurement as feedback to adjust gas flow rate and RF power for desired cleaning speed. Very useful to set up the right cleaning recipe for different samples.

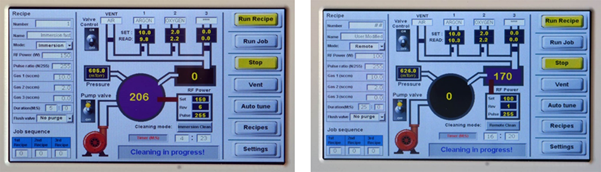

Smart plasma ignition algorithm

As the Tergeo-EM plasma cleaner has an integrated a plasma sensor, that can measure the plasma intensity in real-time, the system controller knows the status of the plasma constantly. If the plasma fails to ignite at low RF power setting, the system will automatically increase the RF power until the plasma ignites. Once the plasma ignites, the system will immediately reduce the RF power to the recipe setting. This feature enables Tergeo-EM to be able to operate at much lower RF power than the competitive products.

Easy to use with intuitive design

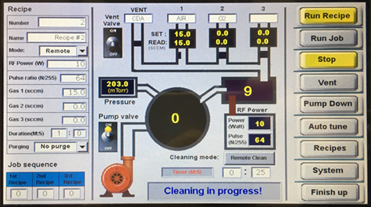

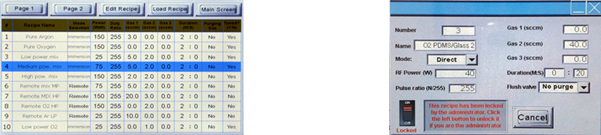

Intuitive user interface. Easy to use. No extensive training required.

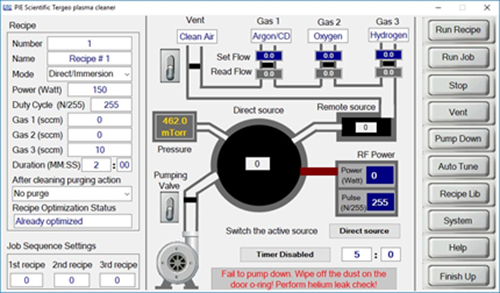

Two user interfaces: LCD touchscreen user interface and optional PC remote control user interface.

Fully automatic operation. Supports 20 recipes. One button to start. Repeatable and reliable results. Recipe lock/unlock function to prevent unintended modification of the optimized recipes.

Essential features for repeated runs and for shared facilities. Smart system self-diagnostic. Notifies user with operation tips, system status and problems reports via the LCD screen or PC user interface.

PC Control

Monitor the process through the PC control software, save system logs and run records. - Ensure stable process control for day to day production.

The Tergeo EM sofware can alert, if the process drifts out of the upper and lower control limit. The limits can be set for each recipe. The alert can be set on RF power, chamber pressure, gas flow rate on each channel and plasma intensity.

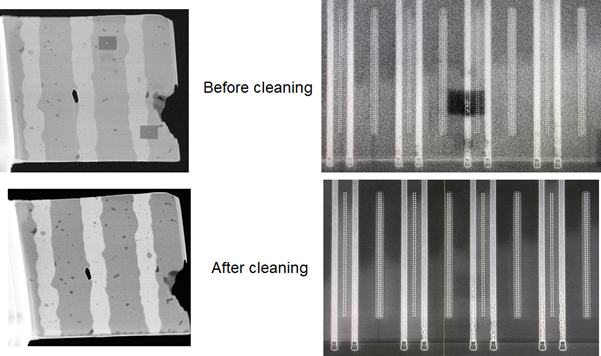

Results

A versatile and intuitive laboratory plasma system for TEM/SEM sample/grid/holder cleaning/activation. The low-cost high-performance laboratory plasma cleaners are built upon the technology developed at the Plasma and Ion Source Technology Group in the Lawrence Berkeley National Laboratory.

Specifications

| RF Power Supply | 0-75W continuously adjustable in 1W intervals |

| 13,56MHz High Frequency RF Power Supply, Automatic Impedance Matching. | |

| Continuous and pulsed RF output. | |

| Sample Chamber | Cylindrical Quartz Chamber and quartz observation window |

| Internal Diameter 110mm x Depth 280mm; quartz chamber wall thickness 5mm. |

|

| One Rectangular Quartz Shelf with holes for SEM sample stud is included | |

| Isolation valve between the plasma chamber and the pump for fast sample loading and unloading. | |

| Isolation valve between the plasma chamber and the pump for fast sample loading and unloading. | |

| Corrosion-Resistant 304 stainless steel wire mesh filter to block plasma from leaking into the pumping hose. | |

| Teflon encapsulated o-ring for enhanced chemical resistance and longer lifetime. | |

| Two TEM rod adapters and two quartz observation windows. Support two different TEM specimen holder at the same time. Capable to support four different kinds TEM sample holders by ordering an extra front door. | |

| Plasma Source Design | Dual Plasma Sources in one system, traditional direct plasma source and gentle downstream plasma source. |

| Conventional Direct Mode plasma processing for high speed cleaning and Gentle Downstream Mode plasma processing for fragile carbon and graphene grids. | |

| Control the etching speed by adjusting RF power, RF output pulse duty ratio and plasma processing mode (direct or downstream), and gas mixing ratio. | |

| External RF Electrode design to reduce ion sputtering on the metal electrodes and to reduce the metal sputtering contamination from the electrodes. | |

| Plasma Discharge Mode | Capacitive coupled discharge for the direct plasma source |

| Inductively coupled plasma source as the remote plasma source | |

| Plasma Diagnostics | Real-time Plasma Intensity Sensor for Quantitative Plasma Status Monitoring to guide the user to adjust the recipes. |

| Smart and automatic plasma ignition and tuning with the feedback from the real-time plasma intensity sensor. | |

| Gas Delivery and process gases | One Solenoid Valve for fast chamber venting and purging after cleaning. Venting gas flow rate can be adjusted through a needle valve to prevent unsupported TEM/SEM samples from being blown away by strong gas flow. |

| Two (2) or Optional Three (3) MFC regulated gas input ports for process gas delivery | |

| All gas input ports use standard ¼“ Swagelok tubing compression fitting | |

| Supported process gases: Oxygen, Hydrogen, Argon, Ambient air, or mixed gases. Mixing ratio can be adjusted by recipe setting. | |

| Input gas pressure range 0,5 - 1bar | |

| Pressure Sensor | Pirani Pressure Sensor (10-4 bar to atmospheric pressure) |

| Vacuum Pump options | Scroll Pumps with pumping speed: 6-12m3/h and ultimate pressure 0,02mbar or below suggested |

More Information

| Manufacturer |

PIE Scientific

|

|---|---|

| Application |

Electron Microscopy

EM

SEM

TEM

|

| Weight | 0.000000 |