About Sputter Coating

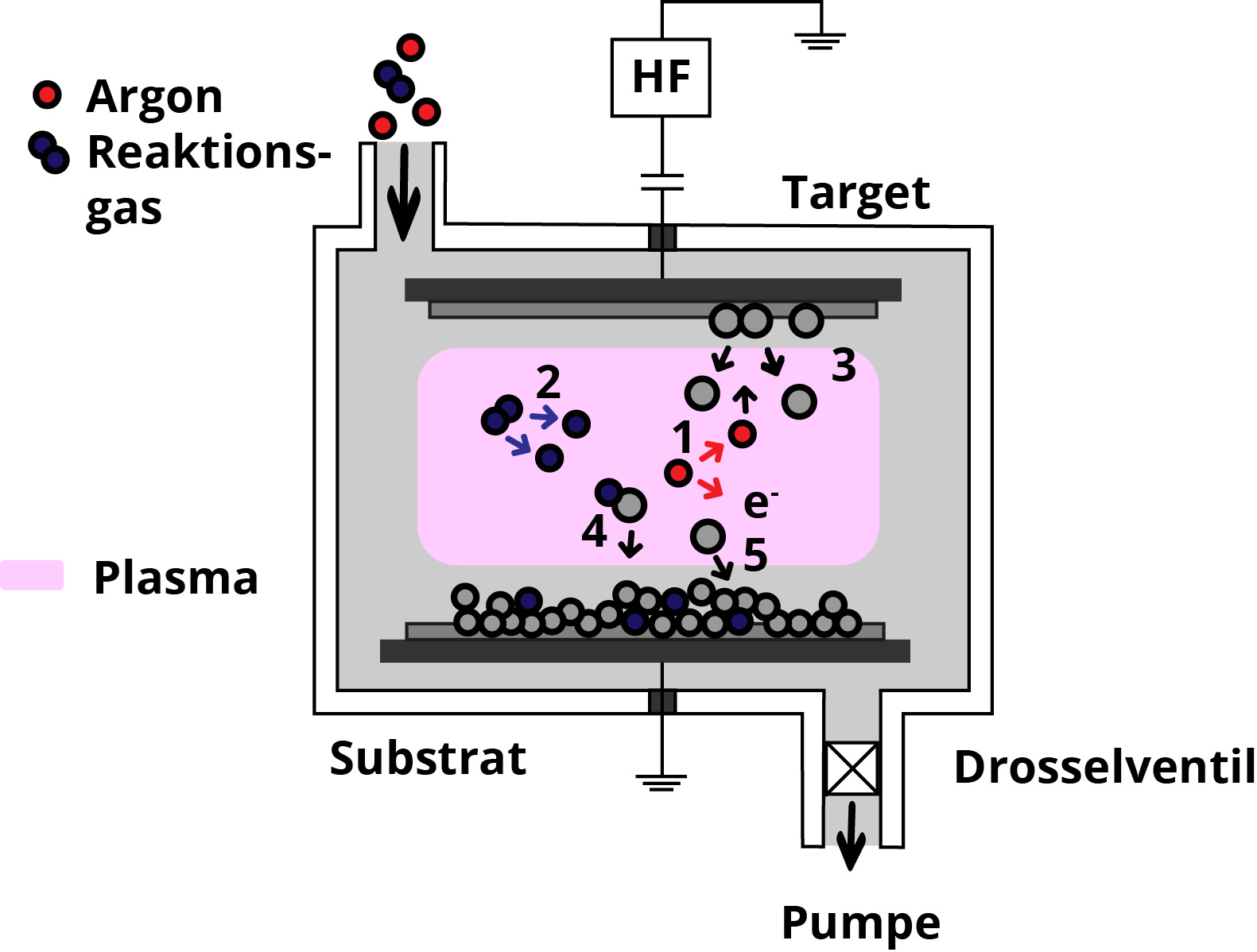

Sputter coating is a physical vapor deposition (PVD) method used to deposit thin films from a target material onto substrates or samples.

Ionized gas atoms are formed in a low-pressure plasma and accelerated onto the target material. Commonly, Argon gas is used due to its inert nature and atomic weight which is in a desired range for good momentum transfer to many materials. Momentum transfer, pressure and energy define the deposition rate, grain size, anisotropy and more parameters of the deposition process. Sputtered atoms ejected from the target material have a quite high ballistic energy, typically up to tens of eV, which results in good adhesion to many surfaces compared to other thin film deposition methods.

For electron microscopy, the conductive nature of various sputter coatings is desired to eliminate surface charging of non-conductive samples under the electron beam. The high atomic weight of metals also leads to good signal to noise ratio during electron imaging of samples with lower atomic weight.

The size of the sputter target is given by the type of sputter coater used. Foil targets are sputter targets without a backing plate of different material. The coater model defines if targets with or without backing plate can be used. The thickness of a target defines the amount of material that can be sputtered during the target life cycle.