3D Calibration

(3)-

Art.Nr: microCal

m2c calibration software microCal is recommended for a successful 3D calibration. It is developed especially for an automated and easy 3D calibration with m2c calibration structures. By using a marker based calibration technology, it provides improved measurement accuracy and has the following advantages:

- One Step: Simultaneous processing of lateral and vertical calibration parameters (scale, shear)

- One Model: For the first time, determination of coupling between vertical and lateral axes is possible

- One Click: Due to advanced image processing and statistical methods, calibration is extremely efficient and accurate

- One Reference: Software and calibration structures are suitable for different measurement devices

-

Starting at

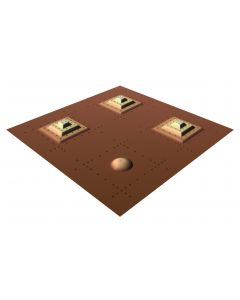

m2c 3D calibration technology helps to turn a SEM with 4 Quadrant BSE detectors (4Q BSD) into a quantitative measurement system. 3D calibration with special m2c reference structures for 4Q BSD SEMs has the following advantages:

- Simultaneous (one-step) lateral and vertical calibration

- Calibration is extremely efficient and accurate due to advanced image processing methods

- Calibration structure has a spherical segment for the signal adjustment of the four backscatter detectors (BSD)

m2c 3D calibration structures for 4Q BSD SEM systems are available for several scan areas, from 40 μm x 40 μm and up to 80 μm x 80 μm. The complete structure with four elements (full area) or a single pyramidal element (quarter area) may be used for the automated calibration process

Starting at

-

Starting at

m2c 3D SPM calibration technology provides improved measurement accuracy and has the following advantages:

- One Step: Simultaneous lateral and vertical calibration is provided in one measurement step

- One Model: For the first time, determination of coupling between vertical and lateral axes is possible

- One Click: Calibration is extremely efficient and accurate due to advanced image processing methods

- One Reference: Universal application with one reference structure is possible (SPM, CLSM, SEM or other)

m2c 3D SPM calibration structures are available for several scan areas, from 20 μm x 20 μm and up to 80 μm x 80 μm. The complete structure with four pyramidal elements (full area) or a single pyramidal element (quarter area) may be used for the automated calibration process.

Starting at