Tergeo Series Tabletop Plasma Cleaner

Tergeo, Tergeo-Plus and Tergeo-Pro are automated, versatile tabletop plasma cleaning and etching systems for research, development and low-volume production labs. They demonstrate exceptional performance in surface cleaning, activation, removal of organic contamination, enhancement of bonding and photoresist ashing.

Product Details

Description

Tergeo Series Tabletop Plasma Cleaner

Plasma cleaning, plasma etching, surface treatment

Tergeo, Tergeo-Plus and Tergeo-Pro are automated tabletop plasma cleaning and etching systems for research, development and low-volume production labs.

Tergeo plasma cleaners demonstrate exceptional performance in surface cleaning, activation, removal of organic contamination, enhancement of bonding and photoresist ashing. Their precision and versatility make them ideal for applications in nanotechnology, materials science, microfabrication and failure analysis. Tergeo systems offer exceptional long-term value thanks to their maintenance-free design and low cost of ownership.

Key Features:

- Support wide range of process gases: Tergeo plasma systems are compatible with a broad spectrum of process gases, including oxygen, argon, nitrogen, hydrogen, CF₄, SF₆, ambient air, water vapor as well as custom gas mixtures. The system can handle up to three different gases simultaneously, making it ideal for various applications such as photoresist ashing, descum, surface cleaning and activation or pre-bonding treatment.

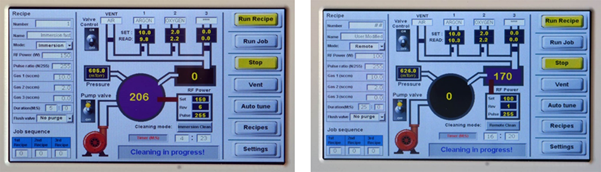

- Fully automatic plasma processes: Designed for ease and consistency, Tergeo systems feature MFC-regulated gas flow control and recipe-based operation. The entire process—from vacuum pumping, gas delivery and pressure stabilization to plasma ignition, impedance matching, timed processing and post-cleaning purging - is fully automated. This ensures highly repeatable and reliable results without manual intervention.

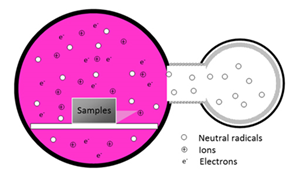

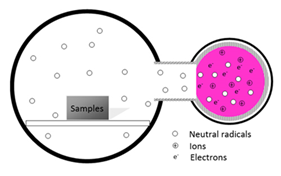

- Dual plasma sources in one system: Tergeo series plasma system can integrate two plasma sources in one system. The direct mode plasma source provides high speed etching and ashing. The optional remote downstream plasma source offers gentle surface treatment and cleaning for fragile and ESD sensitive samples.

- Plasma intensity sensor: An integrated plasma intensity sensor delivers real-time, quantitative feedback displayed on the touchscreen interface. This simplifies process optimization and enhances consistency - no plasma expertise required. For oxygen plasma ashing, the sensor can also serve as end-point detection tool when processing organic materials like photoresists.

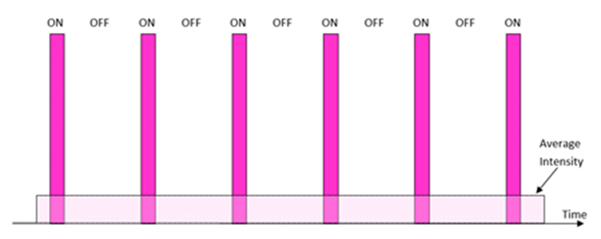

- Continuous and pulsed plasma: Tergeo systems offer fine RF power control in 1-watt increments and support both continuous and pulsed plasma modes. The pulse ratio is adjustable from 100% down to less than 1%, extending the dynamic plasma intensity range by two orders of magnitude. This allows for both aggressive processing - like photoresist removal at >1 µm/min and ultra-gentle treatment of fragile 2D materials such as graphene.

- Water vapor plasma: Tergeo systems can generate water vapor plasma to produce a high density of OH* (hydroxyl) functional groups, crucial for making surfaces hydrophilic. The use of H₂O and O₂ plasma also provides a safer alternative to reactive hydrogen-oxygen mixtures, particularly for treating radiation-hardened polymers. Additionally, this configuration enables plasma sterilization to effectively eliminate viruses and bacteria.

Standard applications:

- Cleaning before wire bonding, die-attachment, flip-chip bonding

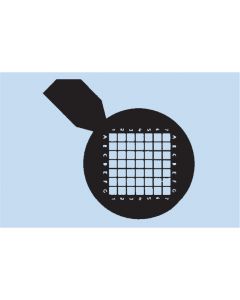

- SEM/TEM sample cleaning for hydrocarbon removal

- Surface treatment before biomedical coating to improve the hydrophilicity e.g. of medical implants

- Optics, glass and substrate cleaning before epoxy bonding

- Photoresist ashing, descum and silicon wafer cleaning

- PDMS, microfluidics, glass slides and lab-on-a-chip surface modification

- Improvement of epoxy bonding for metal to metal or composite

- Improvement of bonding for plastic, polymer, and composite materials

- Medical device activation, sterilization and improving coating adhesion

Academic Recognition:

- The technology in Tergeo series plasma systems originates from the Plasma & Ion source Technology group in the Lawrence Berkeley National Laboratory.

- Tergeo series plasma systems have been well received by the academic communities worldwide. Please search “Tergeo plasma” on Google Scholar and check it out! Here is the direct link to the partial list of publications. Tergeo plasma systems deliver the latest plasma technology to the academic community. They are versatile, reliable plasma systems with repeatable performance at an affordable price.

Technical Advantages

- Better plasma uniformity with external electrode design.

- Unique plasma sensor technology for quantitative plasma intensity measurement.

- Direct/immersion and remote/downstream plasma process in one system.

- Continuous and pulsed plasma can change the cleaning speed by 3-4 orders of magnitude.

- High frequency 13.56MHz rf power supply with automatic impedance matching. MHz plasma systems are many times as efficient as kHz plasma systems at the same rf power rating.

- Advanced process control technology.

- Mass flow controller (MFC) regulated gas input instead of manual rotameter or coarse needle valve.

- Advanced digital pressure sensor for accurate pressure monitoring.

- Fully automatic operation with 20 configurable recipes.

- Intuitive touchscreen user interface and optional PC software control.

- The external RF electrode and quartz chamber eliminate the risk of metal contamination compared to plasma systems with internal metal electrodes.

Operation of Tergeo plasma systems

Its fully automatic, recipe-based operation provides repeatable and reliable performance. The intuitive user interface enables new users to operate the system without extensive training. The smart system design, aided by multiple sensors (plasma intensity, pressure and flow), enables fully automatic operation.

| Model | Chamber Size (Diameter × Depth) | Max. RF Power (@13,56 MHz) | Key Features | Applications |

| Tergeo | 110mm Ø × 280mm | 75W or 150W | Basic model, fully automatic, touchscreen interface, continuous and optional pulsed plasma, optional remote plasma source | PDMS bonding, surface activation, bio-MEMS, lab applications |

| Tergeo-Plus | 160mm Ø × 280mm | 150W or 300W | Larger chamber than Tergeo, continuous and pulsed plasma, , optional remote plasma source | Larger samples, lab applications, surface treatment |

| Tergeo-Pro | 230mm Ø × 340mm | 150W, 300W, or 500W | Very large chamber, suitable for 8″ wafers, continuous and optional pulsed plasma, optional remote plasma source | Large-area samples, wafers, PCBs, industrial applications |

| Tergeo-EM | 110mm Ø × 280mm | 75W or 150W | Specialized for TEM/SEM samples, , continuous and pulsed plasma as standard, direct and remote plasma as standard, adapters for TEM holders | TEM/SEM sample cleaning, hydrocarbon removal, sensitive samples |

More Information

| Manufacturer |

PIE Scientific

|

|---|